Binding performance data you can count on.

We have been operating the Research & Development Centre, which is equipped multifunctionally on 2,000 m² of floor space, since 2008. Perfect conditions for valid test results. Not only is all equipment optimised and newly developed in the laboratories – it is also measured in line with the right standards and regulations. For binding performance data you can count on.

The room air flow laboratory

In order to simulate the real air conditioning of rooms, the walls, floor and ceiling can be heated or cooled separately. Structural specifics can be reproduced. The end result is statement about air flows and comfort.

The multi-purpose laboratory

The heart of the multi-purpose laboratory is the chamber test bench conforming to standards for measuring ventilator and resistance characteristic curves as well as of filters, flaps and channels. Two climate simulation units supply conditioned air of up to 14,000m³/h for this purpose.

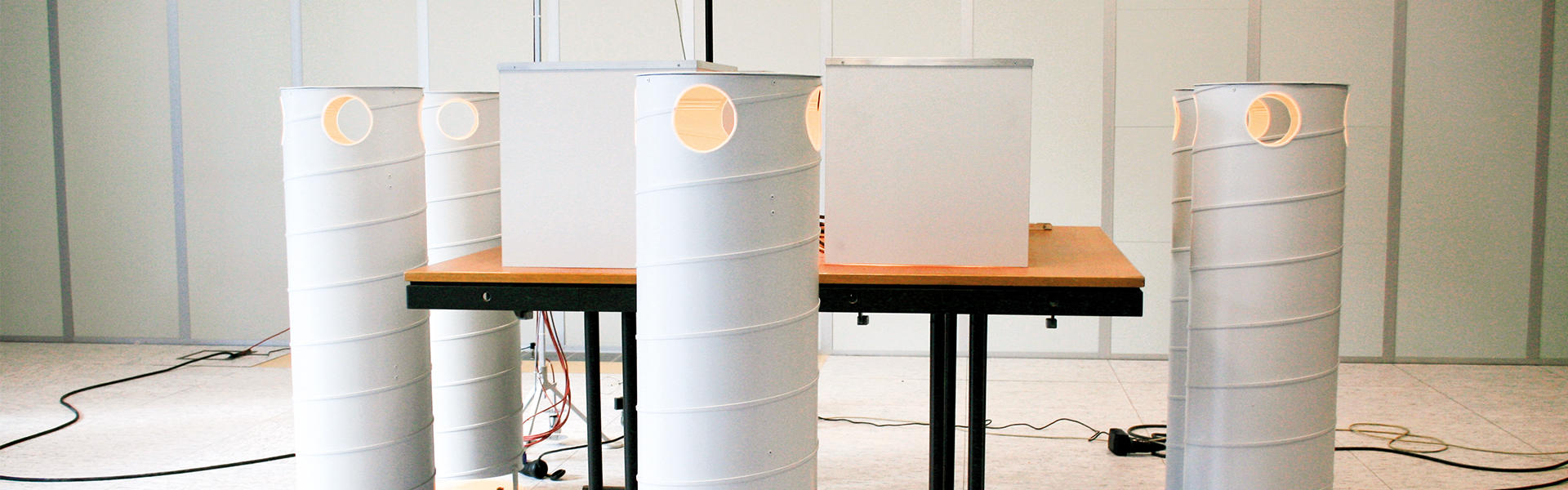

The sound measurement laboratory

Shhh! 300 mm concrete, 400 mm stone and glass wool as well as 450 mm wedge absorbers provide for absolute silence. The room needs this condition in order to be able to measure the extremely quiet Kampmann systems.

The showroom area

Four multimedia boxes showcase the functionality of various Kampmann products in detail: an insight into the market-leading technology and a visual feast for designers and heating engineers. The area is complemented by a demonstration stand displaying the brand-new Venkon fan coil with HEPA filter for connection upstream. There is also a live presentation of the air purifier KA-520, the phenomenal new ‘wonder’ product in the Kampmann range.

The industrial tower

High ceilings are the standard in factories, assembly buildings and warehouses. You may doubt whether unit heaters or diffusers have the appropriate penetration depth to move the air to floor level. Kampmann puts the performance of its equipment to the test in the industrial tower: depending on the setting, warm air reaches floor level with ease, and cold air is evenly distributed under the ceiling to then fall gently and draught-free.

The system rooms

The two system rooms reproduce a two-axis and a three-axis office (axis dimension = 1.35 m). Customer projects can be replicated and measured in them, or product demonstrations arranged. In product development, these are the rooms in which prototypes are tested. The flow laboratory later measures the performance values of the zero series.

The hall room

As impressive as it is to enter the anechoic sound measurement laboratory with its almost oppressive silence, entering the hall room is quite the opposite: sound waves are constantly reflected on the acoustically hard wall surfaces, none of which are parallel to their opposite wall. This creates a strong reverberation, resulting in a uniform, diffuse acoustic field, ideal for determining the sound power of fan coils and other products. The partition wall integrated in the hall room separates the test bench into a transmission and reception room. The building acoustic measurements possible here perfectly complement the range of acoustic measurements available.